hydraulically bound floor coatings

DORSILIT® quartz sand

DORSILIT® brand quartz sand is based on raw materials which we extract from our own open-pit mine and then refine into a top-quality, high-performance quartz sand using specialized process technology. Due to its consistently high quality, DORSILIT® quartz sand has an excellent reputation in the industrial and commercial construction industry as a constituent for hydraulically setting, highly durable toppings.

Putting floors on a solid base

DORSILIT® quartz sand is the preferred brand for industrial floor installation in production and assembly plants, etc. and for public buildings.

Customer benefits of DORSILIT® quartz sand for hydraulically setting coatings

Technical

- High purity, uniform

- Compact and hard

- Very bright basic color

- Rounded grains, good for high packing density

Operational

- Enhances the flow characteristics of trowel-applied and poured toppings

- Very good pourability and easy spreading

- Finished flooring has excellent strength

Economical

- Brand-name product, good value for money

- Certified and recommended by many building contractors

- High-quality product with a proven track record and long-term availability

ISG quartz sand blends for hydraulically setting toppings and poured compounds

ISG quartz sand blends are the archetypal products in the Dorfner quartz sand range. The ISG A, B and C blends with their special screening lines are regarded in many industries as the quality benchmark, and they are even used in the flooring industry as a generic term for high-quality quartz sand products. It is hardly surprising that ISG quartz sand blends are always state-of-the-art and are the preferred raw materials for hydraulic trowel-leveled and poured toppings.

Raw materials at the leading edge

ISG quartz sand blends have been used for installation of many million square meters of flooring. Because they are strong and hard-wearing, they are used primarily for commercial and industrial flooring at wholesale and retail outlets and at production and assembly plants.

The inner qualities of ISG quartz sand blends

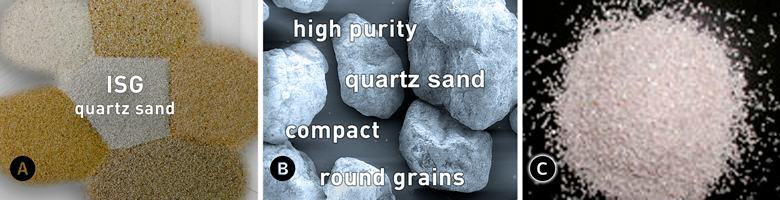

A: Color comparison between various quartz sand products B: REM image of ISG quartz sand. C: 3D supporting framework consisting of ISG quartz sand in a hydraulically setting topping (cross-section). ISG quartz sand blends have a bright gray color and rounded grains. This monocrystalline sand is very hard, making it the ideal raw material for hydraulic trowel-applied and poured toppings.

The secret is in the blend

Dorfner ISG quartz sand blends are mixed in situ, which takes a lot of effort and expertise. Our proprietary process ensures batch-to-batch reproducibility on the screening lines, which is an essential quality attribute of our ISG quartz sand blends. This translates to high dependability and consistently good results for users of our quartz sand blends.

Customer benefits of ISG quartz sand at a glance

Technical

- Formulated filler systems with special in situ screening lines

- Compact, rounded grains; light uniform gray color

- High-strength coatings

Operational

- Very good workability

- Optimized to meet the rheology requirements of hydraulic trowel-applied and poured toppings

Economical

- Recognized brand-name product and a generic term throughout the industry

- High quality standard provides maximum assurance to users

MELADUR® – hard aggregate dry shake

When maximum durability and excellent workability are the top priority, Dorfner’s MELADUR® hard aggregate dry shake for cementitious floor toppings is the solution of choice. Our formulated dry shake consists of basalt and quartz chips, and it is further reinforced with silicon carbide hard aggregate. MELADUR® products are available as ready-made blends which can easily be worked in with a rotary power trowel on cement surfaces and floor toppings which are still in the curing phase and have not completely hardened. Because it contains a special additive, MELADUR® has a long open time and ensures thorough fusing of the dry shake with the concrete base.

MELADUR® – the simple route to enhanced-performance industrial flooring

Hydraulically setting industrial flooring made with MELADUR® hard aggregate dry shake is very hard-wearing and resistant to chemical exposure. Many millions of square meters of industrial flooring in assembly and manufacturing plants have been installed using MELADUR® dry shake, and for good reason. MELADUR® is synonymous with simple installation and hard-wearing, long-lasting flooring.

Technical

- Perfect fusing of the hard aggregate with the concrete base

- Extremely hard-wearing, abrasion-resistant concrete surfaces

- Excellent resistance to mechanical and chemical stress including melting salt, oil, gasoline, solvents, etc.

Operational

- Easily worked in with a rotary power trowel on curing concrete surfaces

- The concrete base has a long open time

- Ready-to-use product, very easy to work with, can be used immediately on site

Economical

- Extremely hard-wearing, abrasion-resistant concrete surfaces

- Low material consumption during installation

- Low-maintenance industrial flooring

DORSIDUR® hard aggregate

DORSIDUR® is used for installation of industrial flooring that is extremely durable. DORSIDUR® blends contain basalt, quartz and silicon carbide hard aggregate chips which are some of the hardest and most chemically resistant materials in the world. DORSIDUR® hard aggregate is worked into the concrete flooring while it is still curing using rotary power trowels, or it is added to hydraulically setting toppings which are installed the usual way. Dorfner’s sophisticated DORSIDUR® screening lines make it possible to install extremely durable flooring while minimizing material consumption, creating significant savings potential.

The epitome of durability

Production area floors in manufacturing and assembly plants in the metalworking industry and heavy industry as well as at foundries, power stations, chemical plants, etc. have to take a lot of punishment. Concrete flooring enhanced with DORSIDUR® is able to do just that.

Customer benefits of DORSIDUR® at a glance

Technical

- Very rugged industrial floors which are subjected to extreme stress

- Extremely resistant to pressure, impact, abrasion and vibration

- Good chemical resistance to melting salt, oil, gasoline, solvents, etc.

Operational

- Can be easily worked into hydraulically setting toppings

- Can be worked into concrete surfaces extremely well during the curing phase

- Special additives guarantee good workability

Economical

- Long-lasting industrial flooring

- Low maintenance, easy to take care of

- High strength reduces consumption, creating good savings potential