DORVALIT® WSP – a Major Breakthrough for Wood Primers

DORVALIT® WSP is an innovative Dorfner REFINERALS®-class filler with exceptional, proven performance in wood primers. The patented Wood Stain Protection Technology (WSP) is highly effective in preventing wood extractives such as polyphenols from migrating into the topcoat and causing unsightly discoloration in light-colored finishes. In contrast to standard stain-blocking additives which contain metals, DORVALIT® WSP is eco-friendly and no special labelling is required.

Not only is DORVALIT® WSP extremely effective, it also has tangible economic benefits. The filler enhances performance in nearly any existing primer formulation. In new formulations, DORVALIT® WSP can be a key factor in reducing labor, and one coating step can possibly be eliminated. All factors considered, DORVALIT® WSP has the potential to reduce total costs by more than 25%.

Learn more about DORVALIT® WSP:

Wood coatings that retain their beauty

DORVALIT® WSP is a new filler for wood primers that sets new standards in barrier performance. DORVALIT® WSP provides outstanding protection for light-color wood finishes, preserving the attractive appearance for years without spots and blemishes.

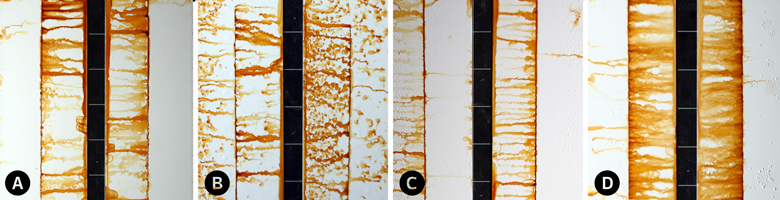

DORVALIT® WSP System Comparison

The results are highly impressive. Adding DORVALIT® WSP to wood primers effectively prevents spotting and it is very cost-efficient.

Wood samples with standard-formulation wood primer applied. A: plus 15 % calcium carbonate. B: plus 15 % calcium carbonate and 2 % inhibitor. C: plus 15 % DORVALIT® WSP.

Samples merbau, primer and commercial topcoat with uniform coating thickness (200 µm).

Wood Stain Protection Technology (WSP)

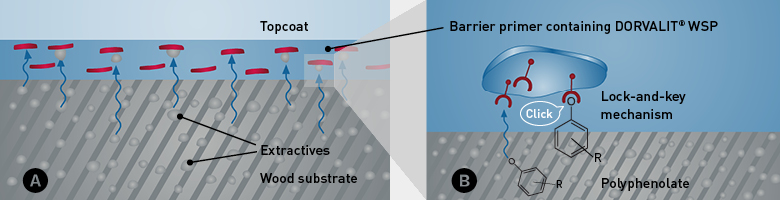

A: Mode of action of DORVALIT® WSP. B: Lock-and-key mechanism.

How DORVALIT® WSP works

The innovative DORVALIT® WSP fillers are firmly bound in the primer matrix. If any colored extractives penetrate into this layer, they are immediately detected and intercepted by the adjusted filler particles and irreversibly bound. The extractives can get no further. They cannot migrate as far as the topcoat where they might otherwise cause discoloration.

The new lock-and-key mechanism

The effectiveness of Dorfner DORVALIT® WSP is based on a new and highly effective mode of action. The modification, which is firmly attached to the filler, provides specific docking sites for colored polyphenol wood extractives. If the extractives come into contact with DORVALIT® WSP particles, they are immediately bound by the action of the lock-and-key mechanism and rendered harmless.

Customer benefits of DORVALIT® WSP at a glance

Technical

- Truly unique Wood Stain Protection Technology

- Top-grade mineral-based filler with surface modification

- Colored extractives permanently bound by lock-and-key mechanism

- Highly efficient migration barrier

- Enhances the effectiveness of barrier primers

Operational

- Suitable for nearly any existing wood primers

- Firmly embedded in the binder matrix

- Can be easily added to water-based formulations

- Enhances filler properties and other technical coating parameters

Economic

- Guards against spotting

- Minimizes the risk of complaints

- Replaces inhibitors containing heavy metals

- Green product, no labeling required

- Can reduce total costs by more than 25%

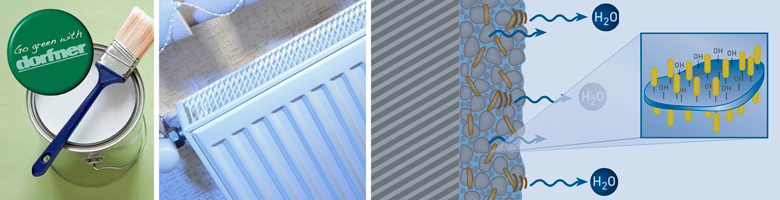

DORVALIT® SHO – eco-friendly label-free corrosion protection coatings

DORVALIT® SHO is a new type of hydrophobic filler for house paint which is used when low to moderate corrosion protection is needed to effectively prevent rust. Formulations can contain DORVALIT® SHO to reduce the amount of corrosion protection pigments or even eliminate them altogether. Rust protection coatings containing DORVALIT® SHO no longer need special marking. They also reduce system costs, are eco-friendly and create new market opportunities for paint manufacturers.

2 ways you benefit from DORVALIT® SHO for corrosion protection

DORVALIT® SHO is based on our calcined kaolins which have a plate-like structure which acts as a very effective mechanical water barrier. The hydrophobic surface functions create a chemical barrier which prevents water from reaching and attacking the surface of iron and steel.

Customer benefits of DORVALIT® SHO at a glance

- Functional filler which partially or completely replaces corrosion protection pigments

- No special marking needed; ideal for corrosion protection coatings which can be very competitive in the market

- Excellence across the board: lower rust formation and blistering and better adhesion to prevent infiltration.

- You benefit in 2 ways: keeps water out, forms a barrier, better then mica and talcum

DORVALIT® SHO – the clear winner in comparative testing

A: with DORVALIT® SHO: no rust formation or blistering across the surface, slight infiltration at the scribe. B: with mica: significantly higher rust formation and blistering across the surface, slight infiltration at the scribe. C: with talcum: heavy blistering across the surface, slight infiltration at the scribe. D: commercially available paint: noticeable rust formation across the surface, slight infiltration at the scribe.

DORKAFILL® PRO_DURA

The highly refined kaolin is the solution for long lasting colors in kitchens, children's rooms and staircases but also in public foyers. The multifunctional filler is a coordinated combination of various properties. It impresses with its balance of opacity and rheology as well as matting and wet abrasion resistance.

One filler for many requirements

- Ideal especially for tinted, colored systems thanks to high color strength

- Perfect matting agent for dispersion paints

- Ideal for use in living areas thanks to best wet abrasion resistance values according to DIN EN 13 300 Class 1 and low tendency to form shiny areas

- Ideal wherever hardness and durability on the wall are required

Customer benefits of DORKAFILL® PRO_DURA at a glance:

- Strong matting

- Good processability

- High color strength

- Excellent wet abrasion resistance to DIN EN 13 300 Class 1

- Virtually no tendency to form shiny areas

- Reflections-, glare- and streak-free

- Highly chemical-resistant

- Conforms to all known eco-labels and EU directives

- Compatible with all common binders